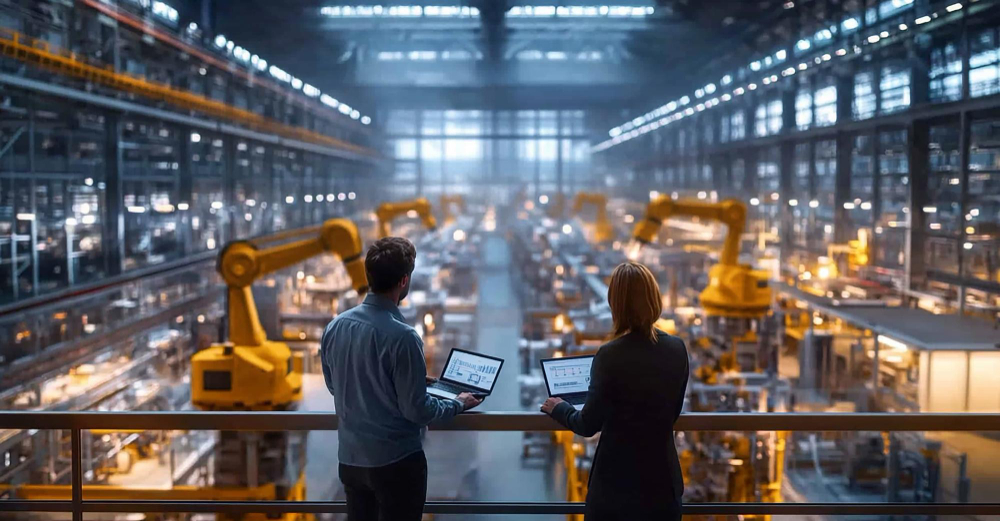

Engineering and Corrosion Solution

Engineering Design

Inspection and Technical consultancy

Manufacturing and Execution

Advanace NDT and Digitalization solution

Engineering and Corrosion Solution

Engineering and Corrosion solution

- Comprehensive Support Services: Offering end-to-end support, from initial design and feasibility studies to installation, maintenance, and optimization, ensuring the longevity and reliability of mechanical systems through their entire lifecycle.

- Custom Engineering Solutions: Providing tailored design services for complex mechanical systems and equipment used in the chemical and oil & gas industries, ensuring that all solutions meet specific client needs and industry standards.

- Material Selection and Compatibility: Assist in selecting corrosion-resistant materials for construction and repair projects. Ensure material compatibility with specific chemicals and operating conditions to minimize corrosion risks.

- Failure Analysis and Risk Management: Conduct thorough failure analysis to identify the root causes of corrosion-related failures. Implement risk management strategies to mitigate the impact of corrosion on operations.

- Protective Coatings and Linings: Provide a range of protective coatings and linings to prevent corrosion in pipelines, tanks, and equipment. Use high-performance coatings resistant to chemicals, high temperatures, and mechanical wear.

Engineering Solutions Manufacturing Execution

Engineering Design

- Comprehensive Design Services: Conceptual design and feasibility studies. Detailed engineering design, including piping, vessels, and structures. Equipment selection and specification.

- Lifecycle Support: Offering services that extend beyond design, including maintenance and operational support. Assistance with modifications and upgrades as needed throughout the plant’s life.

- Process Equipment Design: Development of custom equipment like separators, heat exchangers, vessels, and tanks.

- Piping System Design: Design of robust piping systems to ensure efficient fluid transport, considering thermal expansion and pressure variations.

- Stress Analysis: Conducting detailed stress analysis on critical components to ensure structural integrity under operational loads.

- Thermal Analysis: Expertise in performing thermal analysis for heat exchangers to ensure optimal heat transfer and energy efficiency.

Engineering Solutions Manufacturing Execution

Inspection and Technical consultancy

- Non-destructive Testing (NDT) Methods: Ultrasonic, radiographic, magnetic particle, and dye penetrant inspections. Regular and periodic inspections of pipelines, storage tanks, and equipment. Corrosion monitoring and management. Third-party inspection services to ensure compliance with international standards.

- Technical Consultancy: Feasibility studies and project evaluation. Risk assessment and management. Technical audits and due diligence. Expert advice on regulatory compliance and industry standards.

- Quality Assurance and Quality Control (QA/QC): Development and implementation of QA/QC plans. Vendor and contractor quality audits. Inspection and test plans (ITPs) and procedures. Certification and documentation review.

Engineering Solutions Manufacturing Execution

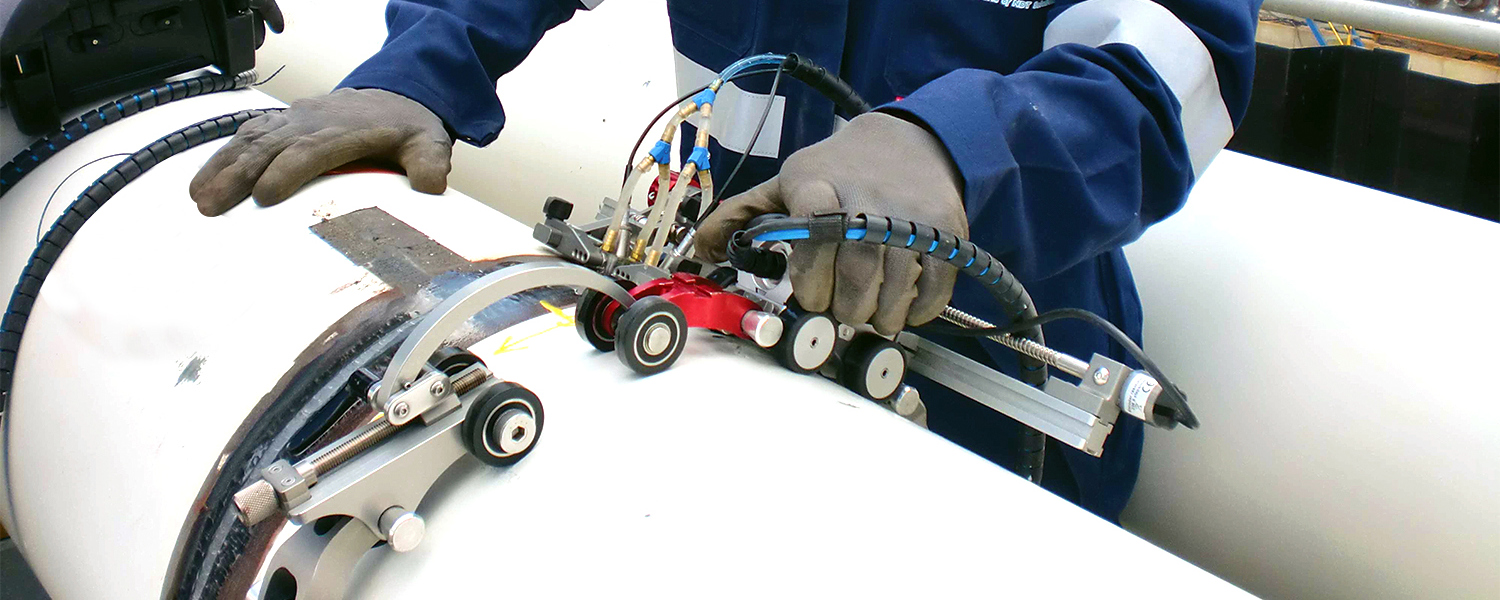

Manufacturing and Execution

- Procurement Services: Handle procurement of high-quality components and materials, ensuring timely availability for project execution.

- Manufacturing: Manufacturing of pressure vessels and heat exchangers with industry standards such as ASME, API, and PED.

- Vendor Management: Experience in selecting and managing suppliers and subcontractors for components and services essential to equipment manufacturing.

- Welding Expertise: Proficiency in advanced welding techniques suitable for high-strength and high-temperature applications, including TIG and MIG welding.

Engineering Solutions Manufacturing Execution

Advance NDT and Digitalization solution

- Predictive Maintenance: Utilize advanced sensor technology and data analytics to predict equipment failures before they occur, minimizing downtime and reducing maintenance costs.

- Condition Monitoring Systems: Install real-time monitoring systems to continuously assess the health of critical machinery, allowing for timely interventions and repairs.

- High-Sensitivity Detection Technologies: Employ state-of-the-art leak detection technologies, such as infrared cameras and acoustic sensors, to identify leaks at the earliest possible stage.